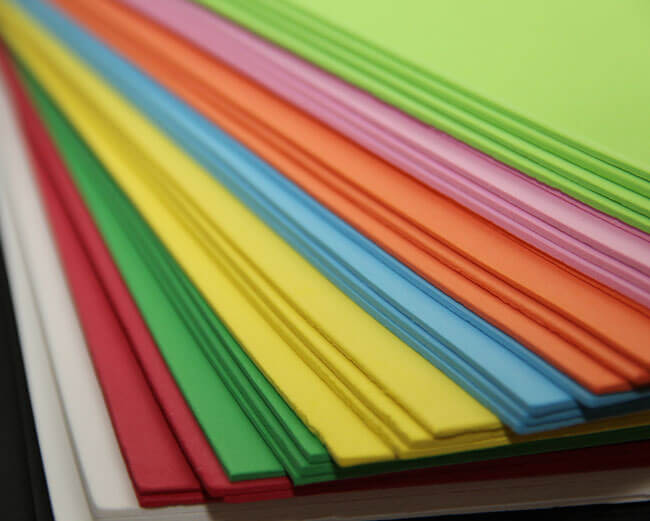

All expanded closed-cell polyethylene foams, including non-cross linked, chemically cross-linked and nitrogen blown varieties, have a “process skin” on both top and bottom surfaces.

These skins can vary even within the same batch, and removing them reveals the uniform cell structure of the material, which can have different cell sizes depending on the specific foam type.

Once the splitting machine is set to the correct dimensions, our skilled operators manually feed the raw foam blocks into the machine. The process begins with removing the process skins from both sides to ensure a uniform material throughout.

The unique knurled rollers securely grip the material and guide it over a sharp blade for precise splitting to your exact specifications.

Our horizontal splitting machine can handle a wide range of foams, including:

- Open cell polyurethane foam

- Heavy density chemically cross-linked polyethylene foam

- Non-cross linked polyethylene foam in any density

- HD (Heavy Density) grade Plastazote polyethylene foams

As well as sheets the machine gives you the option of having split rolls of material if it’s not sheets you require for your application.

Apollo Foam prioritises continuous investment in the latest foam conversion machinery to ensure our customers benefit from the most advanced technology and leading quality.