We have the capability to laminate both cross-linked and non-cross linked polyethylene foam, catering to various project needs. Our machine can handle sheets and rolls up to 1300mm wide, achieving a finished thickness of up to 300mm when required.

Our laminating machine utilises heat and pressure to securely bond the foam sheets, eliminating the need for adhesives. This ensures a clean and environmentally friendly process.

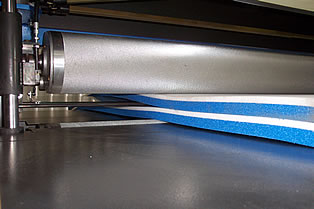

Once the machine is set to the required thickness, the process requires the operator to place two polyethylene foam sheets either side of an electrically heated blade. The blade then melts the surface of each of the sheets which are then brought together into contact and driven through the machine with knurled rollers.

The roller speed and the temperature can be set to correspond with the desired material which is being processed, the rollers controlled speed ensures the required heat transfer is achieved.

The laminated bond created by this method boasts the equivalent strength to that of the individual sheets. This ensures the integrity and consistency of the polyethylene foam are maintained throughout the laminated material.