Apollo Foam provides innovative, custom engineered polyethylene foam solutions globally

Apollo Foam provides innovative, custom engineered polyethylene foam solutions globally

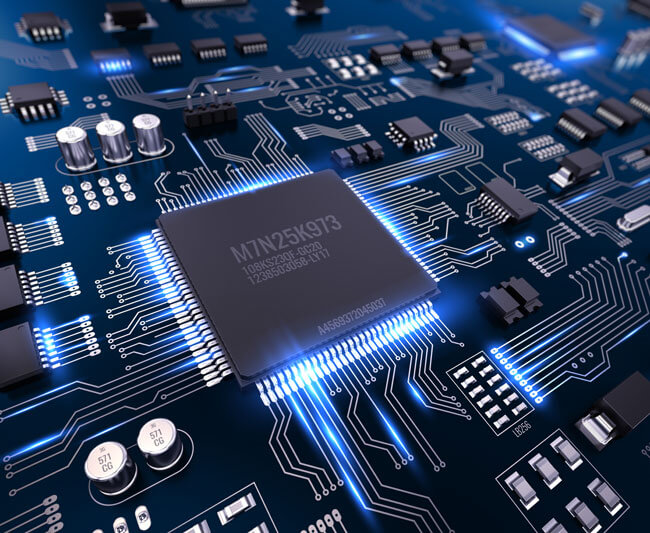

Polyethylene and Open Cell Polyurethane foams are increasingly being used in applications for ESD (Electro Static Discharge).

The foam is used in the packaging of static sensitive electronics devices, from a safety point of view or to protect the electronics, and also from an aesthetics and brand building perspective, too.

ESD can be problematic, causing electric faults and fallout, and failure of integrated circuits. Not only does this compromise the quality of the product, but it can also be harmful.

At Apollo, our foams and products are developed to prevent against this, and our solutions are:

Electronics foam has a number of benefits relating to electricals, that make them the perfect solution for this field.

To ensure the integrity of your products Apollo Foam have a range of products which are ESD compliant for electronics packaging devices, assemblies and electronics equipment.

Electro Static Discharge is most commonly created by the contact and separation of two materials. Critical devices and assemblies are susceptible to these static charges, and the smaller the circuitry is the more vulnerable it is. The materials of choice in this industry are Conductive, Static Dissipative, and Anti Static.

The difference is the speed the static charge travels through the material when it makes contact with a conductive source.

Conductive foams have a volume resistivity of less than 104Ω.

Static Dissipative grade foams offer a slower more controlled transfer of static charge with a resistivity in the range of 104Ω to 1011Ω.

Anti Static Polyethylene foam which is generally non-cross linked and pink in colour have a surface resistivity of 1010Ω to 1012Ω.

We offer a range of Polyethylene and Open Cell Polyurethane foams to protect against ESD and to ensure the quality and safety of products and devices within the electronics sector.

They’re insulating, lightweight, and flexible, as well as being waterproof to further protect.

Our polyethylene foams are converted to our customers’ individual requirements from split sheets, pressed foam fitments, waterjet and routed polyethylene foam components for all market sectors.